In the modern manufacturing landscape, efficiency is the key to survival and growth. Manufacturing businesses today deal with complex production cycles, fluctuating raw material costs, inventory challenges, compliance requirements, and constant pressure to deliver quality products on time. Managing accounting and production separately often leads to data gaps, errors, delays, and increased operational costs.

This is where an Manufacturing ERP Accounting Software plays a critical role. By integrating accounting and production into a single unified system, ERP software helps manufacturing businesses streamline operations, gain real-time visibility, reduce costs, and improve profitability. In this blog, we will explore how ERP accounting software transforms manufacturing operations and creates a seamless connection between finance and production.

1. The Challenge of Managing Accounting and Production Separately

Many manufacturing units still rely on traditional accounting software and manual production tracking systems. While these tools may work individually, they fail to communicate with each other. As a result, manufacturers often face issues such as:

- Mismatch between production data and financial records

- Inaccurate product costing

- Delayed financial reports

- Poor inventory planning

- Difficulty in tracking work-in-progress (WIP)

These challenges not only slow down operations but also impact decision-making and profitability. An Manufacturing ERP Accounting Software eliminates these issues by bringing all departments onto a single platform.

2. Unified Platform for End-to-End Manufacturing Operations

An ERP accounting system acts as a central nervous system for manufacturing businesses. It integrates key functions such as accounting, production planning, inventory, procurement, sales, and compliance.

With a unified system:

- Production activities automatically reflect in accounting records

- Inventory movement updates financial data in real time

- Purchase and sales transactions are directly linked to accounts

This integration ensures data consistency, reduces duplication, and creates a smooth workflow across departments.

3. Streamlining Production Planning and Control

Production planning is the backbone of manufacturing efficiency. Without proper planning, businesses face delays, excess inventory, or idle resources.

An Manufacturing ERP Accounting Software enables manufacturers to:

- Plan production based on real-time demand

- Schedule jobs and allocate resources efficiently

- Monitor production progress at every stage

- Track machine and labor utilization

By aligning production planning with financial data, businesses can control costs while meeting delivery timelines.

4. Accurate and Automated Product Costing

Product costing is one of the most critical aspects of manufacturing accounting. Manual costing methods often overlook indirect expenses such as overheads, machine depreciation, and utility costs.

ERP accounting software automates product costing by:

- Capturing direct material and labor costs

- Allocating overheads accurately

- Calculating batch-wise or job-wise costs

- Providing per-unit cost visibility

Accurate costing helps manufacturers price their products correctly, avoid losses, and improve profit margins.

5. Real-Time Inventory Management

Inventory mismanagement leads to blocked capital, wastage, and production delays. Traditional systems fail to provide real-time inventory insights.

With Manufacturing ERP Accounting Software, inventory is fully integrated with production and accounting. This allows businesses to:

- Track raw materials, WIP, and finished goods in real time

- Avoid overstocking and stock shortages

- Reduce material wastage and pilferage

- Improve inventory turnover

Better inventory control directly improves cash flow and operational efficiency.

6. Seamless Integration of Purchase and Production

Procurement plays a crucial role in manufacturing efficiency. Delays or errors in purchasing impact production schedules and costs.

ERP accounting software streamlines procurement by:

- Linking purchase orders with production requirements

- Tracking supplier performance and costs

- Automatically updating inventory and accounts

- Ensuring timely availability of raw materials

This integration reduces procurement delays and prevents unnecessary production downtime.

7. Faster and More Accurate Financial Reporting

Timely and accurate financial reports are essential for strategic decision-making. Manual reporting methods are slow and prone to errors.

An Manufacturing ERP Accounting Software provides real-time financial reports such as:

- Profit and loss statements

- Cost analysis reports

- Production-wise profitability

- Inventory valuation reports

These insights help management identify inefficiencies and take corrective actions quickly.

8. Improved Cash Flow Management

Manufacturing businesses often struggle with cash flow due to delayed receivables and high working capital requirements.

ERP accounting software helps streamline cash flow by:

- Tracking receivables and payables in real time

- Monitoring outstanding customer payments

- Planning vendor payments effectively

- Forecasting future cash requirements

Improved cash flow management reduces financial stress and supports business growth.

9. Compliance and Audit Readiness Made Easy

Manufacturing units must comply with multiple statutory and tax regulations. Manual compliance processes increase the risk of errors and penalties.

An Manufacturing ERP Accounting Software automates compliance by:

- Generating GST-compliant invoices

- Maintaining accurate audit trails

- Preparing statutory and tax reports

- Ensuring data accuracy and transparency

This reduces compliance risks and simplifies audits.

10. Reduced Manual Work and Human Errors

Manual data entry consumes time and increases the risk of errors, especially in complex manufacturing environments.

ERP systems automate repetitive tasks such as:

- Accounting entries

- Inventory valuation

- Cost allocation

- Report generation

Automation improves accuracy, saves time, and allows teams to focus on strategic activities.

11. Scalability to Support Manufacturing Growth

As manufacturing businesses grow, their operational complexity increases. Traditional systems fail to scale effectively.

An Manufacturing ERP Accounting Software is designed to support growth by:

- Managing multiple plants or locations

- Handling increased transaction volumes

- Supporting new product lines

- Adapting to evolving business needs

This scalability ensures long-term operational stability.

12. Gaining a Competitive Edge Through Digital Transformation

Digital transformation is no longer optional for manufacturing businesses. Companies that adopt ERP systems gain a significant competitive advantage.

With ERP accounting software, manufacturers achieve:

- Better operational control

- Higher production efficiency

- Improved financial accuracy

- Increased profitability

This positions the business for long-term success in a competitive market.

Conclusion

For manufacturing businesses, managing accounting and production separately is no longer sustainable. To remain competitive, control costs, and improve profitability, an integrated approach is essential.

An Manufacturing ERP Accounting Software streamlines accounting and production by providing real-time visibility, accurate costing, efficient inventory management, seamless integration, and actionable insights. It transforms manufacturing operations from fragmented processes into a well-coordinated system.

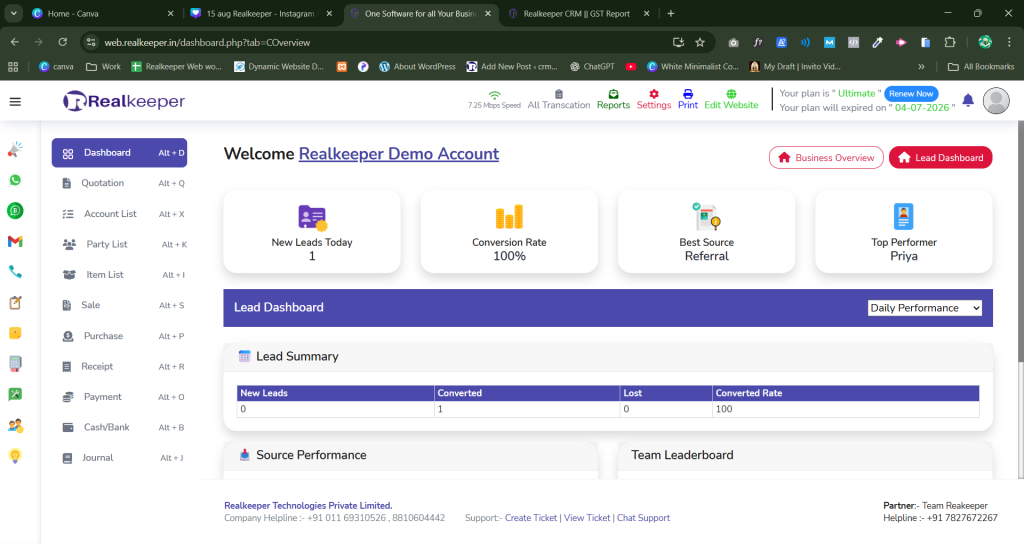

By adopting a smart ERP accounting solution like RealKeeper, manufacturing businesses can simplify operations, strengthen financial control, and build a strong foundation for sustainable growth in the digital manufacturing era.