In today’s highly competitive industrial environment, manufacturing businesses are under constant pressure to reduce costs, improve efficiency, and increase profitability. Rising raw material prices, complex production processes, inventory wastage, compliance requirements, and inaccurate financial data can quickly eat into profits. This is where ERP Accounting Software for Manufacturing becomes not just useful, but essential.

An ERP accounting system integrates finance, production, inventory, procurement, and sales into one centralized platform, helping manufacturing units gain complete control over their operations and finances. Let’s understand why every manufacturing unit—small, medium, or large—needs ERP accounting software to stay profitable and future-ready.

1. Complete Cost Visibility Across the Manufacturing Process

One of the biggest challenges for manufacturers is not knowing the actual cost of production. Costs are spread across raw materials, labor, machinery, utilities, overheads, and logistics. When data is maintained in multiple systems or spreadsheets, it becomes nearly impossible to track real-time costs.

An ERP Accounting Software for Manufacturing provides complete cost transparency by capturing data from every department. From material purchase to finished goods, every expense is automatically recorded and linked to production batches. This allows management to:

- Identify high-cost areas

- Control unnecessary expenses

- Set accurate product pricing

- Improve profit margins

When costs are visible, they become controllable.

2. Better Inventory Management = Lower Wastage

Poor inventory management is a silent profit killer in manufacturing. Overstocking increases storage costs and wastage, while understocking delays production and sales. Traditional accounting software often fails to provide real-time inventory insights.

With ERP accounting software, inventory is directly connected to accounting and production planning. This helps manufacturers:

- Track raw materials, WIP (Work-in-Progress), and finished goods

- Avoid excess stock and stock shortages

- Reduce material wastage and pilferage

- Improve inventory turnover ratio

By maintaining optimal inventory levels, manufacturers can significantly reduce holding costs and improve cash flow.

3. Accurate Product Costing for Higher Profitability

In manufacturing, incorrect product costing can lead to either losses or uncompetitive pricing. Manual costing methods often ignore indirect costs like machine depreciation, power usage, or maintenance.

An ERP Accounting Software for Manufacturing enables precise product costing by allocating both direct and indirect costs accurately. Whether it’s job-based manufacturing, batch production, or continuous manufacturing, ERP systems calculate:

- Per-unit cost

- Batch-wise cost

- Department-wise expenses

This accuracy helps businesses price products competitively while ensuring healthy profit margins.

4. Seamless Integration Between Accounts & Production

One major reason manufacturing units struggle financially is the lack of coordination between accounting and production teams. When production data is delayed or incorrect, financial reports become unreliable.

ERP accounting software bridges this gap by integrating production planning with financial accounting. This results in:

- Automatic posting of production-related entries

- Real-time update of stock valuation

- Accurate profit & loss statements

- Faster month-end and year-end closing

This seamless integration ensures management always has up-to-date financial insights for better decision-making.

5. Improved Cash Flow Management

Even profitable manufacturing businesses can fail due to poor cash flow management. Delayed receivables, uncontrolled expenses, and blocked capital in inventory create financial stress.

With ERP Accounting Software for Manufacturing, businesses can:

- Monitor receivables and payables in real time

- Track outstanding customer payments

- Plan vendor payments efficiently

- Forecast cash flow accurately

Better cash flow control means less dependency on loans and more funds available for growth and expansion.

6. Faster Decision-Making with Real-Time Reports

In manufacturing, delays in decision-making can lead to missed opportunities and higher costs. Traditional reporting methods are slow and often outdated.

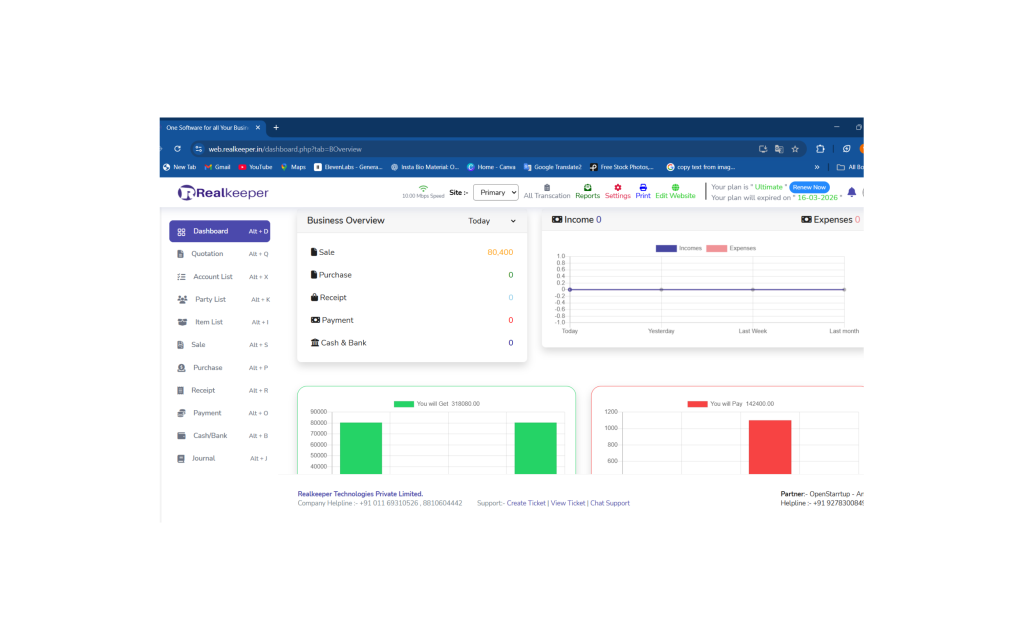

ERP accounting software offers real-time dashboards and reports such as:

- Cost analysis reports

- Production vs. actual expense reports

- Profitability by product or department

- Inventory valuation reports

These insights empower management to take quick, data-driven decisions that directly impact profitability.

7. Compliance, Taxation & Audit Readiness

Manufacturing units must comply with multiple regulations such as GST, income tax, and industry-specific standards. Manual compliance management increases the risk of errors, penalties, and audit issues.

An ERP accounting system automates:

- GST calculations and returns

- Tax-compliant invoicing

- Audit trails and documentation

- Statutory reports

This not only saves time but also ensures peace of mind and legal compliance.

8. Scalability for Business Growth

As manufacturing businesses grow, their operations become more complex. Using basic accounting software or spreadsheets limits scalability and efficiency.

ERP Accounting Software for Manufacturing is designed to grow with the business. It supports:

- Multiple plants or locations

- Increased production volume

- New product lines

- Higher transaction loads

This scalability ensures that the system remains effective even as the business expands.

9. Reduced Manual Work & Human Errors

Manual accounting and data entry consume valuable time and are prone to errors. In manufacturing, even small errors can lead to big financial losses.

ERP systems automate routine accounting tasks such as:

- Journal entries

- Inventory valuation

- Cost allocation

- Financial reporting

Automation reduces errors, saves manpower costs, and allows teams to focus on strategic activities rather than repetitive work.

10. Competitive Advantage in a Digital Manufacturing Era

Manufacturing is rapidly moving towards digital transformation. Businesses that rely on outdated systems struggle to compete with tech-enabled manufacturers.

By adopting ERP Accounting Software for Manufacturing, companies gain:

- Operational efficiency

- Financial control

- Better customer satisfaction

- Stronger profitability

This digital advantage helps manufacturing units stay ahead in a competitive market.

Conclusion

In today’s cost-sensitive and competitive environment, controlling expenses and boosting profitability is critical for every manufacturing unit. An ERP Accounting Software for Manufacturing provides complete visibility, accurate costing, better inventory control, seamless integration, and real-time financial insights.

Whether you run a small manufacturing unit or a large industrial enterprise, investing in an ERP accounting solution is no longer an option—it is a necessity. The right ERP system not only helps you control costs but also builds a strong foundation for sustainable growth and long-term profitability.

By implementing a smart ERP accounting solution like RealKeeper, manufacturing businesses can transform their financial management and move confidently toward a more profitable future.